The increasing customer demand for electric vehicle solutions is forcing the whole automotive value chain from designers, manufacturers, and suppliers to evolve and adapt. Hyperbat, a joint venture between Unipart and Williams Advanced Engineering (WAE), was created to specifically address this growing market demand. WAE provide industry leading design engineering capabilities and Unipart supply manufacturing expertise to deliver the UK’s leading manufacturer for high voltage battery solutions.

"The market is changing. Products are getting more complex. What has been simple to manufacture for the last 30 years with a clear supply chain is becoming increasingly complex in terms of volume, supply, safety, and storage. For instance, a typical fuel tank would involve the design, manufacture, and supply of 30 odd parts. In contrast, a battery pack for an electrical vehicle would be around 15,000 parts. That is a huge change. Hyperbat realised we had to become more collaborative and needed to create an end-to-end solution that links our design house to our production as well as our supply chain and customers.”

Hosein Torabmostaedi - Digital & Innovation Manager at Unipart

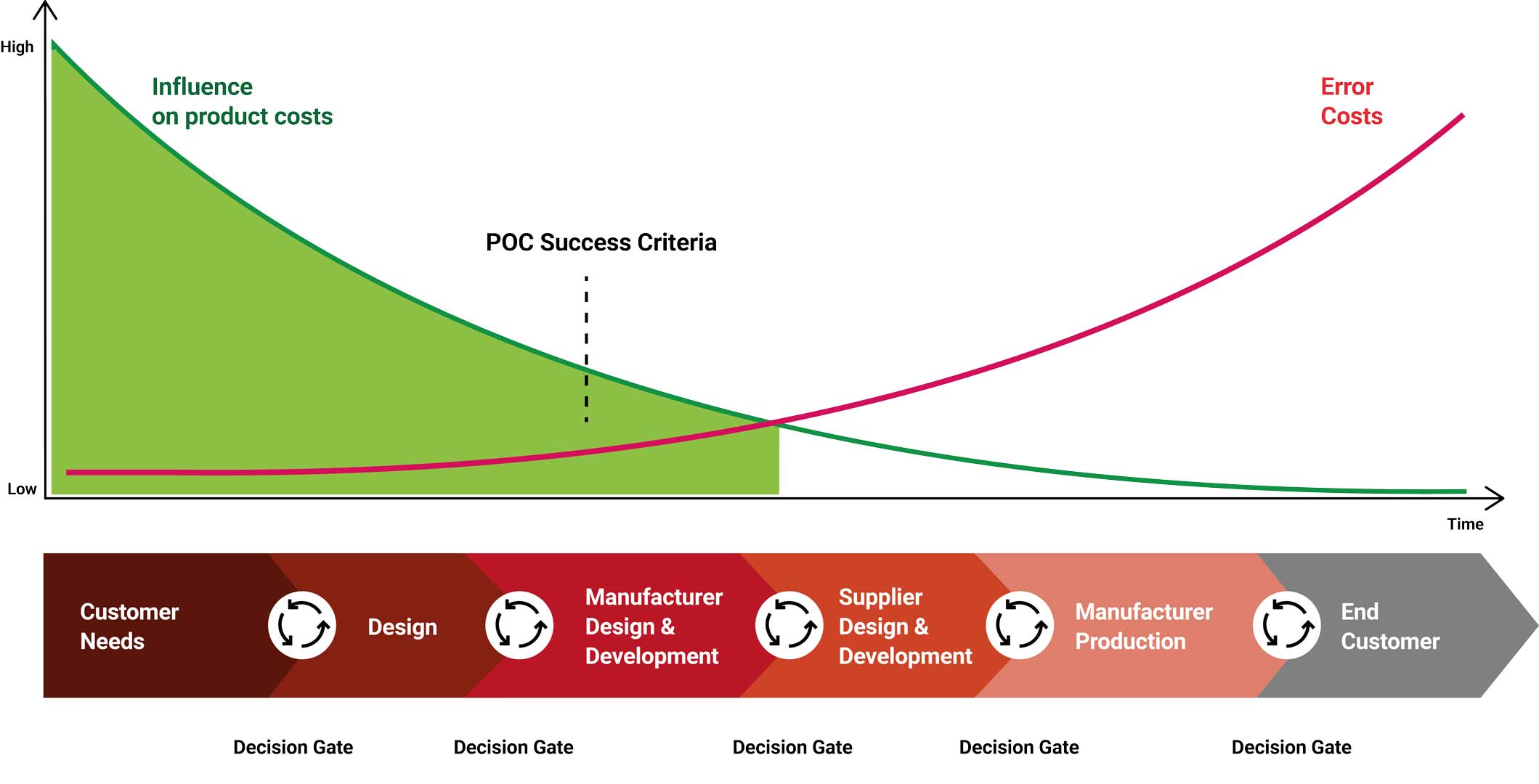

With the increasing level of supply chain complexity comes new design and manufacturing challenges. The car manufacturing industry estimates that decisions made during the design process influence 70% of the total production costs. The handover between design and manufacturing plays a critical role as inefficiencies at this stage impacts the overall profitability of the product. In the Hyperbat situation, the two pivotal teams of design and manufacturing are located in geographically separate locations adding further complexity to the mix.

Hyperbat decided to test a proof of concept delivered by a consortium of companies consisting of Masters of Pie, BT, Dell, Ericsson, NVIDIA, The Grid Factory and Qualcomm. The aim of the proof of concept was to explore how the use of virtual reality (VR) and the digital twin of the product may be leveraged to optimise the handover from the WAE design team based in Oxfordshire to the Unipart manufacturing team based in Coventry. The success criteria was measured by the ability to identify errors and reduce review iteration cycles during the design phase to deliver lower costs, reduce wastage and increase the quality and speed to market of the final product.

"What we want to achieve as part of this consortium is to demonstrate the value of using 5G enabled VR headsets combined with the Masters of Pie digital thread solution in creating that flexible environment between engineering and manufacturing teams, independent of where they are located. The goal from the proof of concept is to synchronise design reviews to shorten the new product introduction process."

Hosein Torabmostaedi - Digital & Innovation Manager at Unipart

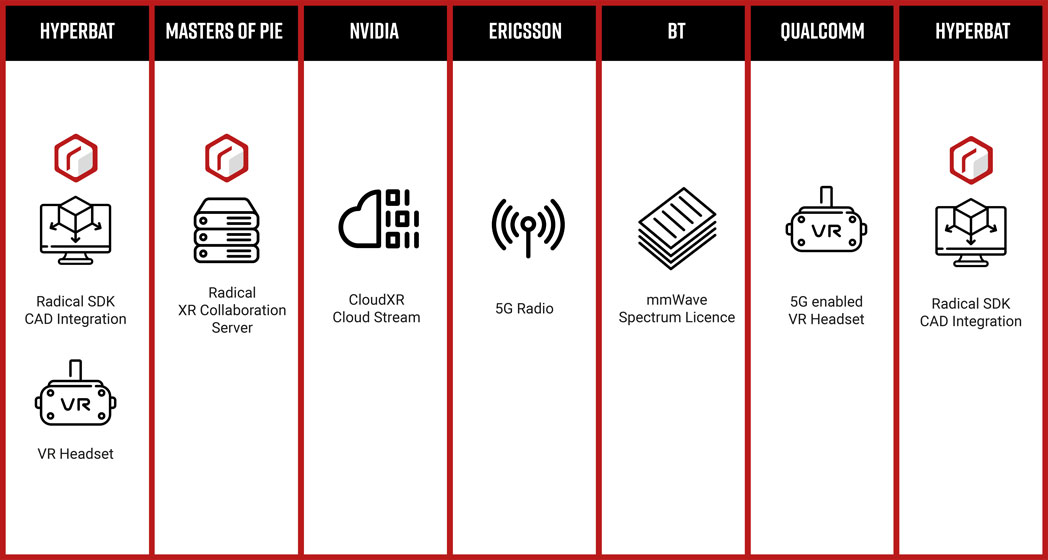

The Hyperbat proof of concept leverages the network enabling technologies provided by the solution consortium. The foundations of the solution include NVIDIA’s Cloud XR technology that renders the Hyperbat CAD models server-side and streams the frames over the Ericsson 5G private network leveraging BT’s mmWave wireless spectrum. The digital twin of the model is delivered in situ via a Qualcomm 5G enabled VR mobile headset.The high-level end to end solution architecture is below:

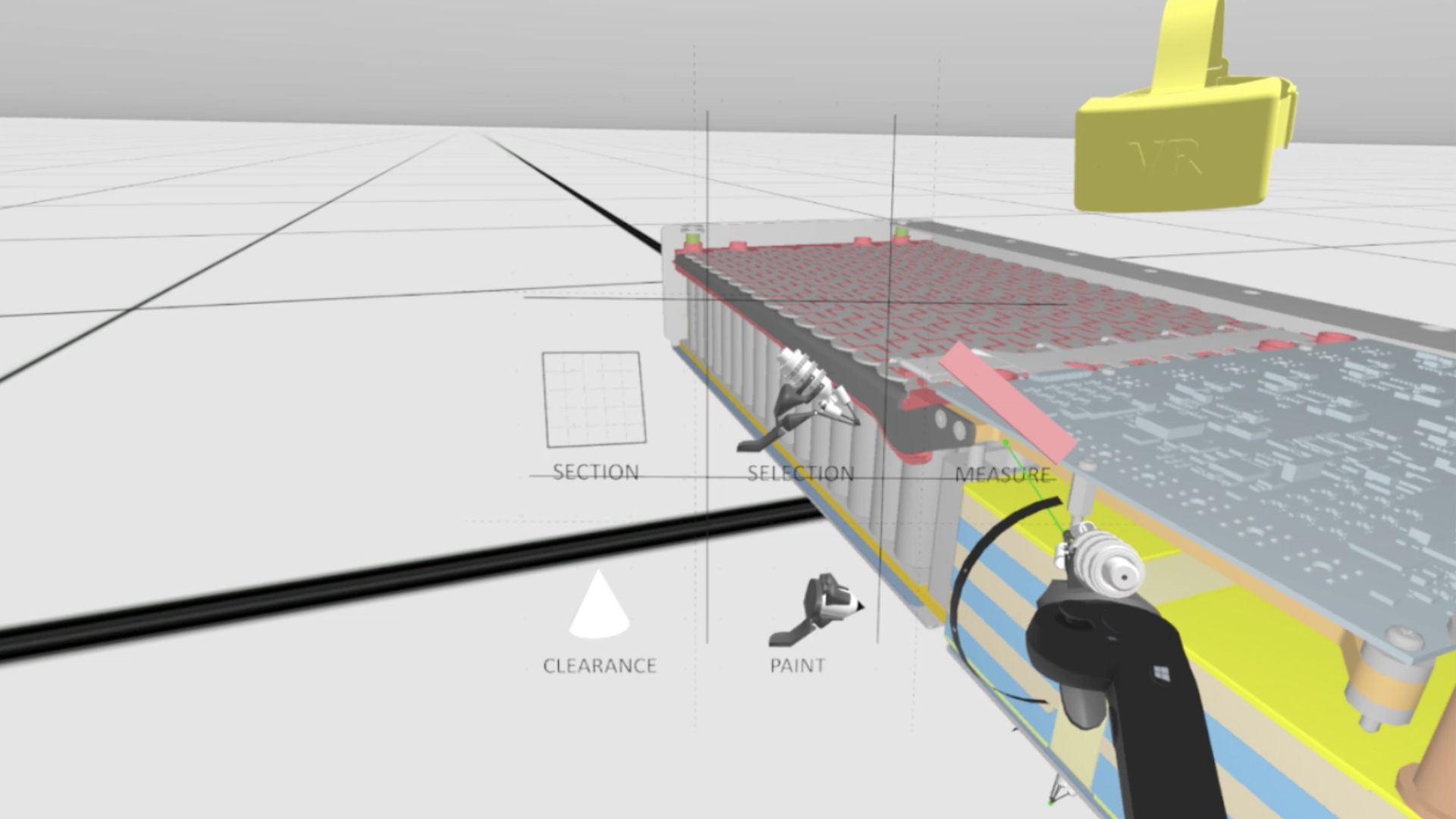

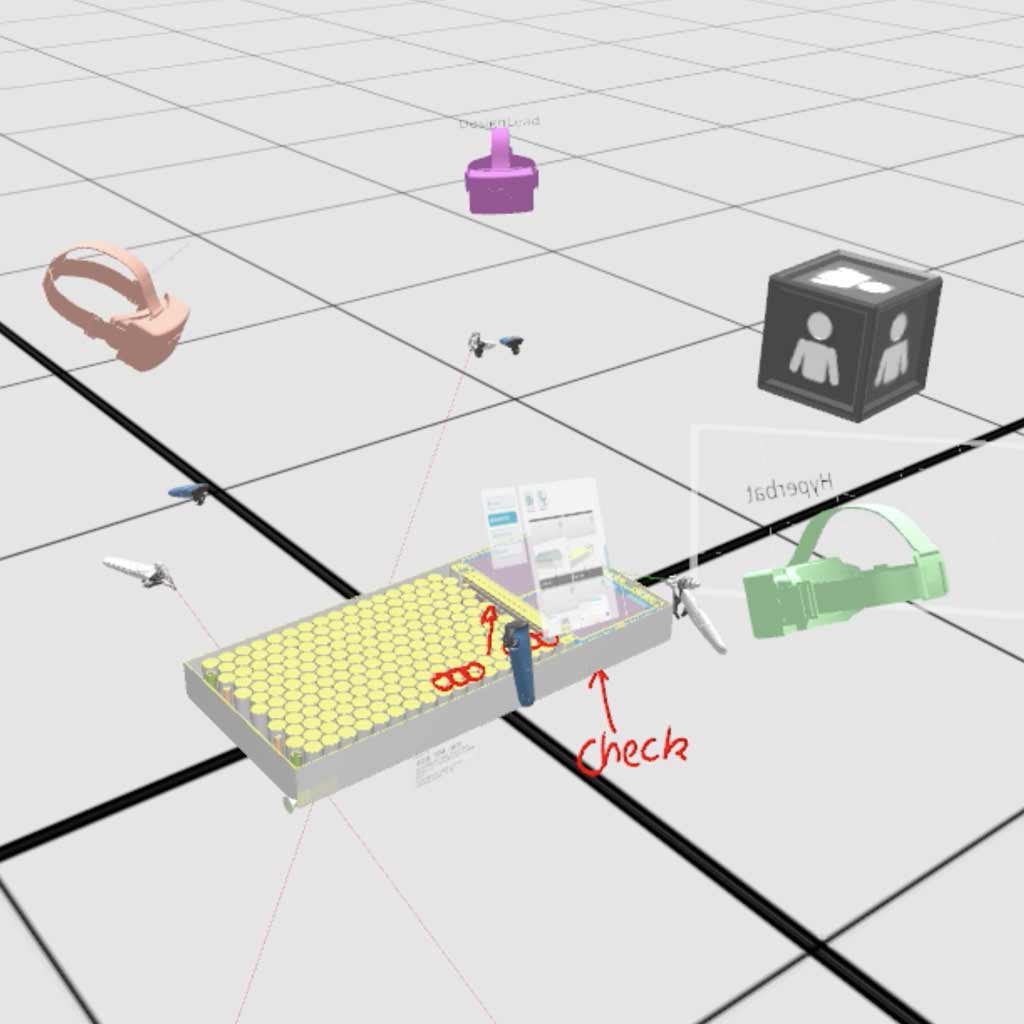

By leveraging a 5G Virtual Reality ‘digital twin’, the WAE team located in Oxfordshire and the Hyperbat team based in Coventry can connect, collaborate and interact using a virtual 3D engineering model. The Hyperbat design review solution leverages the Radical SDK software from Masters of Pie integrated directly into the CAD application enabling the seamless transition from the CAD to the VR experience. This untethered 5G native VR experience at Hyperbat is a world-first and allows design and manufacturing engineering teams to walk around and interact with a 3D lifesize model, through a single self-contained device, and without the constraints of a physical connection.

"By facilitating a greater frequency of collaboration, solutions like Radical provide teams with a fighting chance to discover issues and errors as early as possible in the design process."

Karl Maddix - CEO & Co-Founder at Masters of Pie

The use of VR and the digital twin delivered Hyperbat greater clarity during the final design session on a new build. The ability to review the model using the VR over 5G at scale in situ assisted in identifying areas of misunderstanding and aligned teams at this critical junction in the process.

As represented by the Hyperbat process chart below, there are numerous decision iteration points to be negotiated for the efficient and timely delivery of the final product. The ability of the 5G proof of concept to streamline the decision iterations and identify errors earlier during this process delivered material savings for the overall cost of the project and reduced the time to market for the final product.

The Hyperbat proof of concept operated for two months and validated the ability of the enabling technology to deliver bigger pipes with lower latency covering larger distances. The solution was able to address the entire Hyperbat factory floor without causing the VR experience to lag or become detrimental to the user.

The trial did not run long enough to extract quantifiable benefits but delivered ample qualitative evidence to support the value of this solution to Hyperbat and the wider manufacturing industry. The trial performance convinced all parties of the greater potential to be extracted from evolving the solution to augmented reality (AR) based use cases in the future.

In conclusion, the Hyperbat proof of concept allowed the engineering team to interrogate the digital twin by leveraging virtual reality to identify and rectify misunderstandings and errors during the design process before committing to the sourcing of suppliers and the physical manufacturing and assembly of the product. By capturing issues in software the solution delivered savings on preparation and iteration cycles and ultimately on wastage and improved time to market.

"The Hyperbat 5G proof of concept lays the foundation for the factories of the future. This approach will allow companies to build anything, anywhere, as long as you have the parts and connected tools as it drastically simplifies the network infrastructure and paves the way for faster, more modular and cost-effective innovation introduction."

Hosein Torabmostaedi - Digital & Innovation Manager at Unipart

The Hyperbat solution validates the ability of the enabling technology to deliver XR solutions covering greater distances. This approach will allow companies to break free of the handcuffs of the existing spaghetti network and move towards a wireless experience, as it drastically simplifies the network infrastructure and paves the way to faster and more cost-effective adoption of technological innovation on a factory-wide basis.

Find more about Radical and how you can unlock immersive collaboration.